This is a general rule, whether you are following the commands in these articles or using your own commands. I don’t know which machine you have, or where you have set HOME, so it is your responsibility to check whether a given move will be too large from your machine, or whether a cutter will hit an obstruction, BEFORE you use a command. Some of you will be working on small benchtop machines, like the little Sherline, while others may be working on a Bridgeport with a much larger table and a greater range of movement of the head. The position of the CP in relation to all the other axes will remain unchanged. Will move the CP along the X axis only, to position 70. Axes which are not listed after the G0 command will be ignored and the CP will not move in relation to those commands. The numbers will vary depending on the position to which the CP is to be moved. Many, but not all, will have a fourth axis (usually a rotary axis) A. Most mills will have X, Y and Z axes under computer control. The letters X, Y, Z, A, B and C denote the axes, up to 6 of them, but you would only include those you required for a particular command.

The ~ character is the “tilde” character, and it is used to signify that when the command is entered, there should be a number in this position, so you would never type the command exactly as it appears above. The G0 command is used to move the CP at rapid rate, and it takes the form:

#Mach3 cnc software jog manually code#

G Code commands consist of a letter (usually G, but may also be M, S, F or O, depending on what we trying to instruct the machine to do) followed by a number, and may then be followed by other terms. This is a bit of a misnomer, but it’s the term everyone uses, so it will be good enough for us.

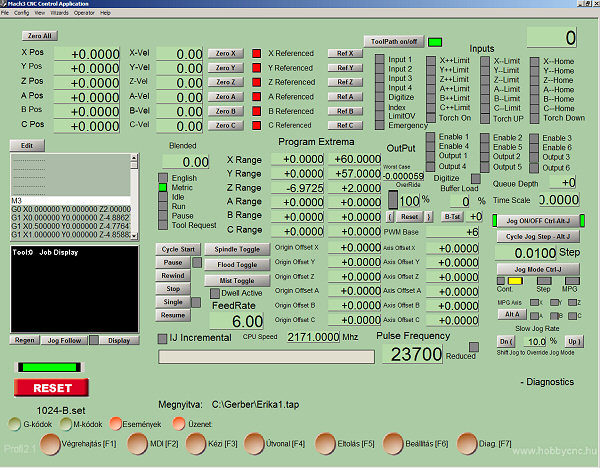

The computer will respond to commands from what has come to be known as the G Code language. There is a lot going on behind the scenes, at that point, but we will leave the explanation until later. If you are not connected to a mill, or if your mill does not have Home switches, you can manually set the DROs to 0.įor the moment, I will assume you do not have Home switches, or are not connected to a mill.Ĭlick the Set Zero buttons on screen, one at a time, to zero the DRO readings. It does need to be set up to do that, though. If your mill is fitted with Home switches, Mach3 can be set up to move the slides until the Home switches trip, then set itself so that point is X0 Y0 Z0. Home can be set in any physical position.

Mach3 needs to know where the CP is in relation to the slides, at least at the start of a session, and the best way to do this is to set a reference position referred to as HOME, where the X, Y and Z axes are all defined as 0.

#Mach3 cnc software jog manually manual#

The manual says clearly that you should not Emulate an EStop, for safety reasons, but, as long as you are not connected to a mill, and you stop the emulation before using your mill under power, this will allow you to check the software works. Note that if you try the logical strategy of putting a cross in the Enabled column, Mach3 will change that to a tick as soon as you leave this screen, to protect you. You may have to scroll across to see the Emulated column. Scroll down to the line entitled EStop and put a tick in the Enabled column, and a tick in the Emulated column. You should see a table you have met before when setting Mach3 up. Go to the Config menu > Ports and Pins > Input signals. You MUST undo this and return E-stop to its proper function before connecting to a working mill. E-stop is there for safety reasons, but can be worked around temporarily, so that you can use the software on its own. If you are not connected to a mill with an E-stop button, or are running the software on its own, disconnected from a mill, you will see a message on the Program Run screen, next to the reset button, complaining about E-stop. Before you go any further, you will need to deal with the Reset button.

0 kommentar(er)

0 kommentar(er)